Page 23 - FUSION+WAVES E-Catalog

P. 23

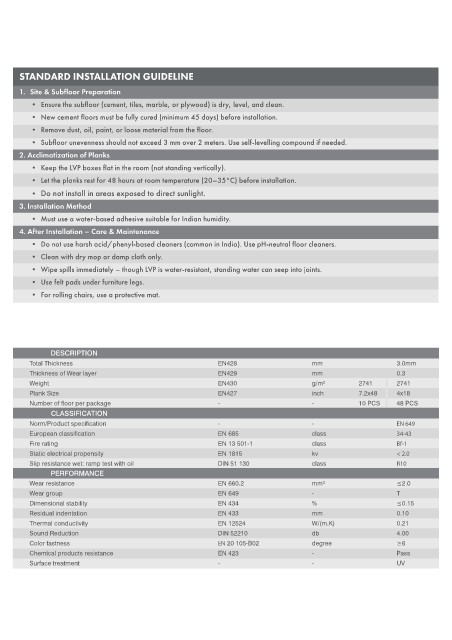

STANDARD INSTALLATION GUIDELINE

1. Site & Subfloor Preparation

• Ensure the subfloor (cement, tiles, marble, or plywood) is dry, level, and clean.

• New cement floors must be fully cured (minimum 45 days) before installation.

• Remove dust, oil, paint, or loose material from the floor.

• Subfloor unevenness should not exceed 3 mm over 2 meters. Use self-levelling compound if needed.

2. Acclimatization of Planks

• Keep the LVP boxes flat in the room (not standing vertically).

• Let the planks rest for 48 hours at room temperature (20–35°C) before installation.

• Do not install in areas exposed to direct sunlight.

3. Installation Method

• Must use a water-based adhesive suitable for Indian humidity.

4. After Installation – Care & Maintenance

• Do not use harsh acid/phenyl-based cleaners (common in India). Use pH-neutral floor cleaners.

• Clean with dry mop or damp cloth only.

• Wipe spills immediately – though LVP is water-resistant, standing water can seep into joints.

• Use felt pads under furniture legs.

• For rolling chairs, use a protective mat.

Total Thickness EN428 mm 3.0mm

Thickness of Wear layer EN429 mm 0.3

Weight EN430 g/m² 2741 2741

Plank Size EN427 inch 7.2x48 4x18

Number of floor per package - - 10 PCS 48 PCS

Norm/Product specification - - EN 649

European classification EN 685 class 34-43

Fire rating EN 13 501-1 class Bf-1

Static electrical propensity EN 1815 kv < 2.0

Slip resistance wet: ramp test with oil DIN 51 130 class R10

Wear resistance EN 660.2 mm³ ≤2.0

Wear group EN 649 - T

Dimensional stability EN 434 % ≤0.15

Residual indentation EN 433 mm 0.10

Thermal conductivity EN 12524 W/(m.K) 0.21

Sound Reduction DIN 52210 db 4.00

Color fastness ΕΝ 20 105-B02 degree ≥6

Chemical products resistance EN 423 - Pass

Surface treatment - - UV